The electric ball valves and actuators stand out among the many innovations in industrial automation that have changed the way industries function today. This modern era of automation is profoundly changing the control of fluids and gases by increasing accuracy, speed, and overall performance. This writing focuses on the future potential of automation with electric ball valves and electric actuators, as well as their emerging importance in the different sectors of industry. The suppliers of control valves make sure that the customers have the right technology for their fluid control systems.

What are Electric Ball Valves with Electric Actuators?

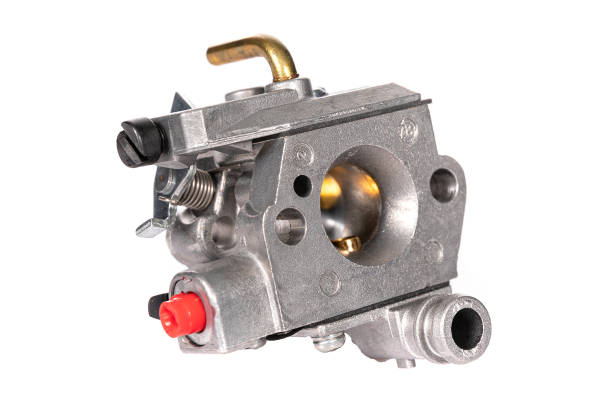

Electric ball valves are devices for controlling the flow of liquid or gas in a pipeline. These valves contain a rotating ball with a central hole, which allows fluid to pass through or blocks it from passing. When an electric actuator is added, these valves can be adjusted automatically or remotely; this allows for very precise flow control. The actuator receives an electric pulse that signals it to rotate the valve to the designated position, thus controlling the flow rate with great precision. The combination of electric actuators and ball valves is widely accepted because of their functionality and ease of operation. They come in different sizes and materials which allows them to be used in numerous applications from industrial manufacturing to HVAC systems. Selecting an electric ball valve does require special consideration, as you must ensure that the valve corresponds to the fluid type and other working conditions such as pressure and temperature. Furthermore, the actuator must provide the appropriate torque while maintaining compatibility with the valve for control accuracy, which is equally important.

The integration of electric ball valves and electric actuators makes it possible to save on energy consumption to a large extent because the flow is very accurately controlled without any waste. This makes them very suitable for use in industries that are focused towards conservation of the environment.

The Advantages of Electric Actuators for Electric Ball Valves

Electric ball valves can be combined with electric actuators for better results by adopting newer technologies. These types of valves are specifically utilized in the automation of processes. The systems can be controlled remotely where the valve ball opens or closes according to the position of the actuator. The major advantage of electric ball valves is the precision with which the flow of the media is regulated. This makes it more useful and important in case of industries like Pharma, Food Processing, and Chemical industries. These industries cannot afford any degree of variance so they need to be closely monitored. Another important advantage is saving energy. Electric actuators are different from pneumatic actuators because they use power when the valve is being adjusted. So, there is no need for constantly renewing energy and compressed air. So, there is a lesser amount of energy used and costs are decreased. Electric ball valves, along with their actuators, are relatively easier to maintain than traditional pneumatic and hydraulic valve systems. Since there are fewer moving parts and no external power source is needed for electric actuators, there is less wear and tear. This reduces maintenance costs and extends the service life of the valve system.

Generally speaking, automated systems of today greatly benefit from electric ball valves due to their efficiency, reliability, and cost-saving features.

The Function of Control Valve Vendors in the Selection Phase

The selection of control valve vendors goes hand in hand with selecting the right type of electric ball valve with actuator best suited for your application. These vendors supply an extensive range of types of valves and different types of actuator fitted to your operational requirements. An expert control valve vendor will focus on the type of fluid or gas being controlled, flow rates, pressure ratings, and temperature tolerance when helping you select an appropriate valve system. They can also assist with the integration of the valve into your existing control systems such as manual, automatic, or remote systems. With their expertise, these suppliers ensure that the electric ball valve and actuator combination you choose is reliable and will accomplish the required process tasks. A reputable vendor will also deal with the system after installation, including, monitoring, maintaining, and providing needed technical help to make sure the system operates optimally for the coming years. Supporting the customer in choosing the right set of components improves the vendor’s reputation while guaranteeing your business operation very few problems.

Incorporation With Intelligent Automation Systems

As industries adapt to smart automation, electric actuated ball valves are at the center of this shift. These systems are capable of interfacing with advanced automation technologies like Building Management Systems (BMS), Supervisory Control and Data Acquisition (SCADA), and PLC (Programmable Logic Controller) systems. With these systems, operators can monitor and control the valves remotely in real-time from any location, thus facilitating improved operational efficiency and safety. When the valves are grouped to a central control system, data is collected, analyzed, and stored for predictive maintenance, performance optimization, and failure diagnosis. These capabilities allow peak performance while eliminating excessive manual processes. In addition, with smart automation, electric ball valves can be programmed to actuate based on preset parameters like temperature, pressure, and flow rate. This feature allows industries to operate more efficiently since energy usage is reduced while optimizing system uptime. All of these attributes increase the functionality and performance of electric ball valves with electric actuators, thus contributing to the industrial automation of the future.

Additionally, pneumatic control valve manufacturers play a role in supplying alternative automation solutions, especially in applications that rely on compressed air, demonstrating the versatility and broad application of control valve technologies in automation.

Conclusion

The introduction of electric actuators with electric ball valves is an advance to automation in all sectors as precision, energy saving, and maintenance needs are optimized. These systems structures are fundamentally essential for businesses who want to be proactive in an ever automated world. By working with trusted control valve suppliers, industries can ensure they are equipped with the most advanced valve solutions available, enabling better control, smarter operations, and improved sustainability. Toward treating food and beverages, during water treatment, as well as chemical manufacturing, the utilization of electric ball valves with electric actuators fosters efficiency and innovation in all sectors. These systems will always provide smarter and greener solutions to multitudes of industries and will always satisfy the increased demand for automation. To address operational concerns in the future, the advancement of both electric and pneumatic controls must be further developed to continue supporting the industries.