In the textile industry, ensuring the durability and performance of fabrics is paramount. One of the key aspects of fabric testing is assessing its tensile strength, which determines how much force a material can withstand before it breaks or deforms. The fabric tensile strength tester plays a crucial role in this process, helping manufacturers and testing labs to adhere to both industry standards and international regulations. This article will explore the importance of tensile testing, the key standards involved, and how modern tensile test equipment ensures compliance with these regulations.

The Importance of Tensile Testing

Tensile testing is essential in evaluating the strength, elasticity, and durability of textile materials. Fabrics are exposed to various forces during use, such as stretching, pulling, or pressure, making it crucial to determine how much stress they can bear without compromising their integrity. Whether it’s for clothing, upholstery, or industrial applications, understanding the tensile properties of fabrics is vital for ensuring their suitability for different purposes.

Tensile testing involves subjecting a sample of fabric to controlled stretching until it breaks or reaches a specified limit. The tensile testing process measures how much force is needed to stretch the fabric to a particular length or deform it. The results provide valuable data on the material’s strength, elongation, and overall durability, which can inform decisions about product design and quality control.

International Standards for Fabric Tensile Testing

To ensure consistency and reliability in testing, various international standards have been developed to guide the evaluation of fabric tensile strength. These standards provide guidelines for sample preparation, testing procedures, and acceptable tolerances, helping to ensure that results are reproducible across different laboratories and testing environments.

For instance, one of the most commonly used standards for tensile testing is ASTM D5034, which outlines the method for testing the breaking force and elongation of textile fabrics. This standard is widely recognized and adopted across many industries, ensuring that testing procedures remain consistent and that results are comparable. Similarly, ISO 13934-1 provides an international method for determining the tensile properties of fabrics, ensuring that textile manufacturers and testing labs comply with global quality standards.

Compliance with these standards is essential for manufacturers seeking to enter international markets or gain certification for their products. By following the guidelines set forth by these standards, companies can demonstrate the reliability and durability of their fabrics, building trust with customers and ensuring that their products meet the demands of the marketplace.

Choosing the Right Tensile Test Equipment

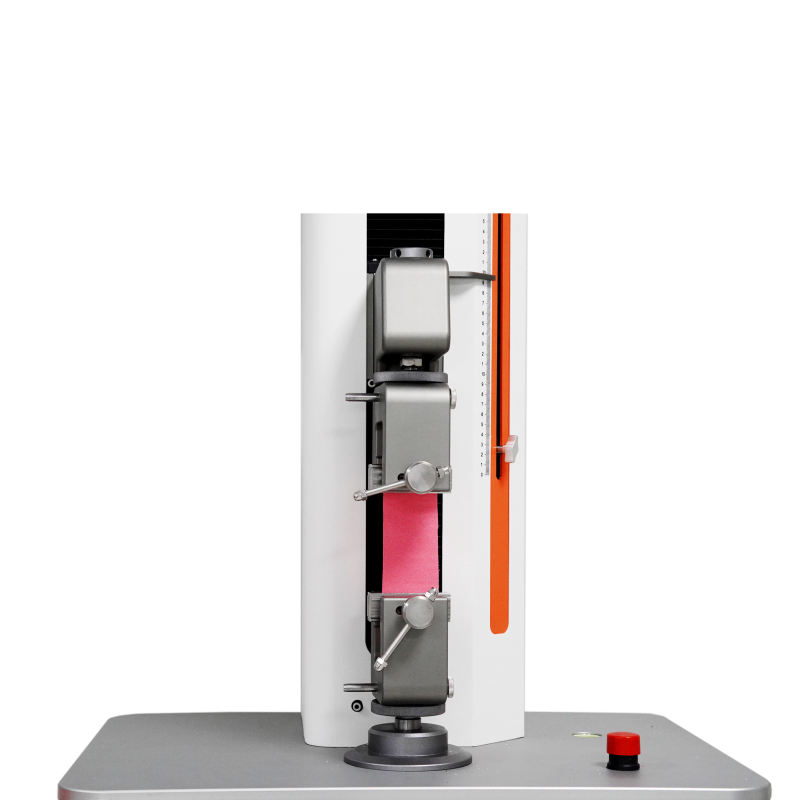

Selecting the appropriate tensile test equipment is critical for achieving accurate and reliable results. Modern tensile testing machines come equipped with advanced features that allow for precise measurements and efficient testing processes. For example, the fabric tensile strength tester is designed to handle a wide range of textile materials, from lightweight fabrics to heavy-duty textiles, making it suitable for diverse testing needs.

These machines are equipped with sensors that can measure force, displacement, and elongation with high accuracy. Many models also include software for data analysis, which allows for the generation of detailed reports and comparison of results against international standards. This level of precision is crucial for ensuring that the testing process is reliable and that results are consistent with the required regulations.

In addition, modern tensile test equipment often includes customizable settings that allow testers to adjust test parameters based on specific material types or testing requirements. This flexibility makes it easier for labs to comply with a range of international standards while also optimizing the testing process for different fabrics.

The Role of Compliance in the Global Market

In today’s globalized textile market, compliance with international testing standards is essential for maintaining competitiveness. Brands and manufacturers are under increasing pressure to meet the high expectations of consumers and regulatory bodies. By using state-of-the-art Textile Testing Machine-TESTEX and tensile test equipment and adhering to established standards, companies can ensure that their products meet the necessary performance criteria, providing consumers with high-quality, reliable fabrics.

Furthermore, testing and certification from accredited laboratories help manufacturers demonstrate their commitment to quality and safety. Products that meet international standards are more likely to succeed in global markets, as they are seen as trustworthy and reliable by both regulatory authorities and customers

Conclusion

Fabric tensile testing is an essential process in ensuring the durability, strength, and performance of textiles. With the help of advanced fabric tensile strength testers and tensile test equipment, manufacturers can ensure that their fabrics meet international standards for quality and safety. By adhering to established regulations, companies can not only ensure compliance but also enhance their reputation in the global textile market. As the industry continues to evolve, embracing the latest testing technologies and standards will remain crucial for maintaining product quality and meeting customer expectations.

For more information on textile testing methods/standards

or Textile Testing Machine-TESTEX textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@chiuvention.com sales@tes.hk