As effective production has become a staple of modern day businesses, every company strives to perform at an optimal level. Areas that require the most improvement are often the packaging operations, which LevaPack as the industry’s frontrunner in can packaging machines takes to innovate. Unlike other packaging solutions, can packaging machines take productivity and simultaneously uphold the quality standard, which is what will be discussed in this article.

The Role of Can Packaging Machines in Streamlining Operations

LevaPack and other can packaging machines are tailored to meet the requirements of every single industry which directly leads to an increase in ease of use. When it comes to production, there can never be an allowance for failure. This is why LevaPack takes it a step further by integrating user-friendly interfaces with high speed functions. As a result of such alterations, the issues of inconsistent output and quality standards not being met are eradicated. With the aid of can packaging machines, every business can take pride in the reduction of manual labor while enhancing their production output.

Automation also reduces human errors when it comes to product packaging, which increases product reliability and packaging consistency. These aspects are critical for companies operating in food, beverage, and pharmaceutical industries. LevaPack’s can packaging machines enable companies to enhance their operational efficiency and minimize the risk of contamination or packaging inconsistency. This helps businesses avoid complaints from customers and issues with regulatory bodies. Incorporating these machines into existing production lines results in better workflow, decreases idle time, and increases productivity. Moreover, companies that previously relied on manual packaging can now deploy their resources to improve other production processes and reduce the probability of getting defective packaged products.

Boost of Production Rate Through Automation

The significant increase in production rate is one of the most obvious advantages of using packaging machinery. In comparison to automated packaging, manual packaging is inefficient and oftentimes results in production delays. Companies are able to sustain much greater levels of production due to the seamless integration provided through automated packaging.

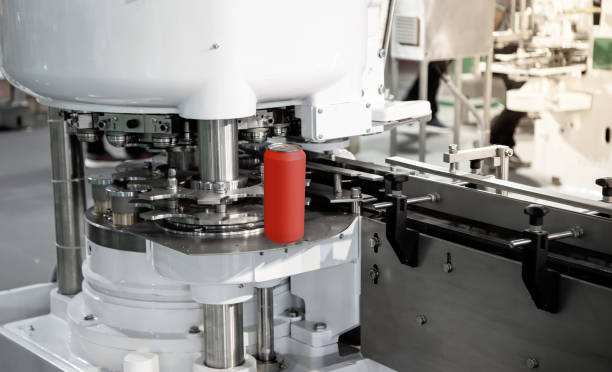

LevaPack’s automatic can packaging machines are made to operate at high speeds therefore easily scaling production. These machines process most cans and bottles within a minimal time frame making it easy to maintain a high quality throughput. Because these systems are automated, they also ensure the entire process is running smoothly without the need for much operator input. Moreover, these machines can be altered to accommodate new packaging designs or changes in product lines without much manual work or downtime which makes these systems flexible.

As production lines increase their speed, firms are able to meet the employees market demand while lowering expenses associated with labor and raising ROI. In today’s competitive marketplace, having the ability to work at top speed ensures business can surpass rivals and increase the satisfaction of their customers at the same time. Automated systems are more effective at managing peak demand times so that product availability can be maintained while not placing too much dependence on manpower and machinery.

Cost Efficiency and Waste Reduction

Packaging machines stand to benefit from cost-efficiency: significant savings and minimization of operational waste. A reduction in labor requirements translates to lower operational expenses. Material waste emission is also reduced, and some cost savings associated with premium packaging is realized, as automated systems use only the necessary amount of material which, over simply used, is cheaper.

LevaPack’s can packaging machines are designed to be energy efficient, contributing to cost savings over time. Reductions in utility expenses stem from modern technology set to optimize energy consumption. The balance achieved between energy used and material waste will be tremendously beneficial over a prolonged period. Such advancements mark the machines as a worthy investment for any business. Additionally, the effectiveness of the machines increases stock control, thus reducing the likelihood of excess stock or stockouts. Greater efficacy wages material management as the automated technique drastically limits the waste brought about by human error or mishandling.

Achieving operational efficiency comes alongside cost efficiency. The eliminated requirement of maintenance reduces downtime which helps ensure production lines are useful for large chunks of time. Additionally, automating the packaging process leads to personnel being able to focus on tasks that provide more value, hence improving productivity across the workforce.

Product Consistency and Increased Safety Measures

Manufacturing processes, including food and beverage sectors, rely heavily on quality control to ensure consumer safety is maintained. It becomes extremely difficult to achieve product quality consistently when manual packaging is used. Missteps through human error can easily occur such as faulty sealing or labeling causing a loss of product integrity.

LevaPack’s can packaging machines are crafted with standards that ensure quality is not sacrificed at any stage of production. By using these machines, almost every can is filled, sealed, and labeled precisely resulting in high standards while also reducing the chances of packaging or contamination. Moreover, the machines are equipped with continuous monitoring which helps setting sensors that keep track of fill levels and seal integrity. As a result, operators receive real-time feedback along with detection of any issue in quality standards before the products are shipped out.

Reducing the chances of defects for the product recalls enables packaging machines to increase customer satisfaction. This process of quality assurance is necessary for industries with high levels of regulatory scrutiny because safety and compliance must always be achieved. Automated can packaging systems are vital in guaranteeing product safety and brand integrity because of their precision and consistency. Furthermore, placing automated quality checks also improves the safety and efficacy of packaged goods, nurturing faith in targeted consumers and stakeholders.

Conclusion

Your operational efficiency will significantly improve with the incorporation of can packaging machines into your production line. As the best packaging solutions available, LevaPack’s packaging systems offer speed and cost-effective quality services in one package, which all businesses need to be productive. Can packaging machines give you the ability to increase productivity, decrease product loss, and maintain production value? Rather than waiting, take the first step towards increasing your business’s growth and work productivity by purchasing automated packaging. Automated systems allow your company to remain competitive while producing high quality products.