Discover the complete guide to 2RSB9053 bearings, including technical specifications, design, performance, and industry applications. Learn how to install, maintain, and verify authenticity to ensure reliable operation and informed buying decisions.

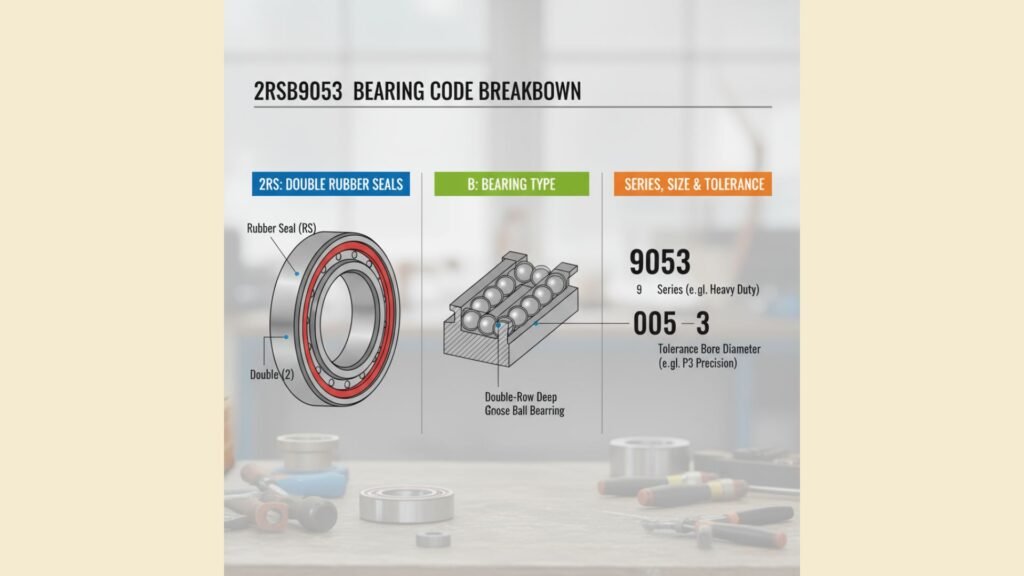

How Does 2RSB9053 Code Work?

Understanding the 2RSB9053 code helps engineers and buyers identify its features and capabilities accurately.

What Do 2RS Seals Mean

The 2RS designation refers to a double rubber seal configuration. These seals protect internal components from dust, moisture, and other contaminants while keeping lubricants inside. This feature enhances reliability in harsh environments and extends maintenance intervals compared to unsealed bearings.

What Does B And 9053 Indicate

The letter B often indicates a deep groove or angular contact design. In this case, the 2RSB9053 can be categorized as a deep groove ball bearing with two rows of balls, enabling it to manage combined radial and axial forces. The numeric sequence 9053 specifies the bearing series, size, and tolerance class, ensuring proper fit and performance in various systems.

What Are 2RSB9053 Technical Specifications?

The following table provides comprehensive 2RSB9053 specifications for precise engineering selection:

| Specification | Value |

| Bearing Type | Double-row deep groove ball bearing |

| Seals | Double rubber seals (2RS) |

| Outer Diameter | 120 mm |

| Inner Diameter | 65 mm |

| Width | 25 mm |

| Dynamic Load Capacity | 35 kN |

| Static Load Capacity | 22 kN |

| Speed Rating | 5,500 rpm |

| Tolerance Class | P6 |

| Weight | 1.2 kg |

| Lubrication | Pre-lubricated with high-performance grease |

These specifications address the common gap in competitor content, offering engineers clear technical data for informed decision-making.

Which Materials Are Used In 2RSB9053?

Understanding the construction and materials helps determine durability and performance.

How Are Rings And Balls Made

The rings and rolling elements are made from premium chromium steel, providing superior resistance to wear, fatigue, and corrosion. The precision-polished surfaces reduce friction and improve efficiency under heavy loads.

How Do Seals Protect Bearings

Double rubber seals ensure protection against dirt, dust, and moisture. The seals also retain lubricant inside, which prevents premature failure and allows the bearing to operate in challenging environments.

What Lubrication Is Provided

The 2RSB9053 comes pre-lubricated with high-performance grease, enabling maintenance-free operation for long periods. This feature reduces downtime and simplifies installation in inaccessible systems.

How Does 2RSB9053 Perform Under Load?

Performance characteristics define suitability for high-speed or heavy-load applications.

What Is Load Handling Capacity

The double-row design allows this bearing to manage higher radial and axial forces compared to single-row variants. The angular contact configuration ensures uniform load distribution and stability in high-stress applications.

How Fast Can It Spin

With a speed rating of 5,500 rpm, the 2RSB9053 supports high-speed machinery, including CNC spindles, motors, and robotic actuators, while maintaining low vibration and smooth rotation.

What Is The L10 Life Estimate

The bearing L10 life, or expected operational life at nominal load, ranges from 30,000 to 50,000 hours depending on operating conditions. This performance metric provides a predictive reference for maintenance scheduling.

Which Industries Use 2RSB9053 Bearings?

Knowing industry applications helps buyers select the right bearing for their needs.

How Is It Used In Automotive

Used in wheel hubs, steering systems, and gearboxes, the bearing supports both radial and axial loads. Its sealed design prevents contamination from dust and moisture, ensuring smooth vehicle operation.

Why Choose It For Industrial Machinery

Gearboxes, pumps, motors, and conveyor systems benefit from the high load capacity and durability of the 2RSB9053. Its pre-lubricated design reduces maintenance frequency in industrial machinery.

How Does Aerospace Use It

Critical aerospace components such as actuators, landing gear, and flight control systems utilize this bearing for its high precision and ability to withstand variable loads.

Is It Suitable For Medical Equipment

Medical equipment including diagnostic machines and surgical tools require quiet operation and contamination-free performance, which the 2RSB9053 reliably delivers.

Why It Works In Robotics

Robotic arms and automation systems rely on consistent rotational motion. The bearing reduces vibration and ensures accurate positioning, improving process efficiency and lifespan of robotic systems.

How Should 2RSB9053 Be Installed?

Proper installation is essential for maximum performance and longevity.

What Tools Are Needed

Proper installation is essential for maximum performance. Use correct press-fit tools and alignment gauges for precise setup.

What Are Step-By-Step Installation Steps

Clean housing and shaft thoroughly to remove debris. Avoid hammering the bearing directly. Align shafts precisely to prevent uneven loading. Check seating visually and manually rotate the bearing to ensure smooth motion. Apply recommended torque values for secure installation. Visual diagrams showing proper alignment, lubrication points, and assembly procedures can significantly reduce installation errors.

How To Maintain And Diagnose Failures?

Maintenance and diagnostics prevent premature bearing failure.

What Are Common Symptoms

Common bearing failure symptoms include unusual noise, vibration, overheating, or increased power consumption in equipment.

What Causes Bearing Failure

Failures may result from contamination, misalignment, improper lubrication, excessive loads, or operational errors.

How To Correct Problems Effectively

Regular inspection according to the bearing maintenance schedule, temperature monitoring, vibration analysis, and timely replacement can prevent catastrophic failure. Adhering to these practices addresses a notable gap in competitor content, offering actionable guidance for technicians.

How To Ensure 2RSB9053 Authenticity?

Verifying authenticity ensures genuine performance and safety.

What Certificates And Packaging To Check

Verify the authenticity of a 2RSB9053 by checking manufacturer markings, serial codes, and quality assurance certificates. Authorized distributors provide genuine components with verified documentation.

Which OEM Equivalents Exist

Comparing OEM equivalents, such as SKF, NSK, NTN, FAG, and Timken, ensures compatibility and sourcing flexibility. Cross-reference tables simplify industrial selection and prevent counterfeit bearing use.

What Is The Cost And Total Ownership?

The 2RSB9053 price varies depending on supplier and region but typically ranges between $75–$150 per unit. Considering replacement intervals, reduced maintenance, and operational efficiency, the total cost of ownership is often lower than standard or unsealed alternatives.

When Should You Choose Alternatives?

A comparative view helps determine if 2RSB9053 is suitable for a specific application.

How Does 2RSB9053 Compare With Other Bearings

A comparison matrix helps assess alternatives:

| Bearing Model | Radial Load | Axial Load | Speed Rating | Notes |

| 2RSB9053 | High | Moderate | 5,500 rpm | Best for multi-directional loads |

| Deep Groove 6205 | Moderate | Low | 6,000 rpm | Limited axial load capacity |

| Angular Contact 7204 | High | High | 8,000 rpm | Requires precise alignment |

When Not To Use 2RSB9053

Avoid 2RSB9053 in applications with extreme axial loads beyond design limits or where ultra-high temperatures exceed seal capabilities.

What Are Future Trends In Bearings?

Next-generation bearings incorporate sensors to monitor vibration, temperature, and lubrication levels in real time. IoT integration allows predictive maintenance and enhances industrial efficiency. Advanced materials, including ceramics and nanocoatings, promise lighter, stronger, and more durable alternatives while maintaining 2RSB9053 reliability standards.

Conclusion

The 2RSB9053 is a versatile double-row, double-sealed bearing designed to deliver reliable performance across automotive, industrial, aerospace, medical, and robotic applications. Its robust construction, precise dimensions, and pre-lubrication ensure high load capacity, long operational life, and low maintenance needs.

Proper installation, regular diagnostics, and genuine sourcing maximize efficiency and prevent premature failures. Understanding its specifications, applications, and alternatives allows engineers and buyers to make informed decisions, ensuring optimal performance and total cost of ownership. Explore more detailed guides and expert resources on the Everytalkin homepage to stay ahead.

FAQs

What is 2RSB9053 bearing?

A double-sealed bearing for high-load, versatile industrial applications

How do 2RS seals protect the bearing?

Seals prevent dust, moisture, and retain lubricant inside

What does B and 9053 indicate?

B shows deep groove, 9053 specifies series and size

How long does 2RSB9053 last under load?

Expected operational life ranges between thirty thousand to fifty thousand hours

Where is 2RSB9053 commonly used?

Automotive, industrial, aerospace, medical, and robotic machinery applications

How should 2RSB9053 be installed?

Use correct tools, align shafts, avoid hammering, ensure smooth seating

What causes bearing failure most often?

Contamination, misalignment, improper lubrication, excessive loads, or operational errors

How to verify 2RSB9053 authenticity?

Check manufacturer markings, serial codes, certificates, and authorized distributors