In the evolving landscape of electric motor manufacturing, efficiency, accuracy, and productivity are the cornerstones of success. As industries strive to meet growing demand for electric vehicles, home appliances, robotics, and industrial automation, the role of the electric motor winding machine becomes increasingly critical. These machines automate and optimize the coil winding process, significantly improving production speed while ensuring high quality.

One of the most advanced technologies supporting this goal is the concept of segmented stator winding. When combined with efficient winding machinery, this technique allows manufacturers to meet modern motor design requirements with greater speed and precision.

This article explores how electric motor winding machines and segmented stator winding technology enhance production speed, reduce errors, and support scalable motor manufacturing.

Understanding Electric Motor Winding Machines

What Is an Electric Motor Winding Machine?

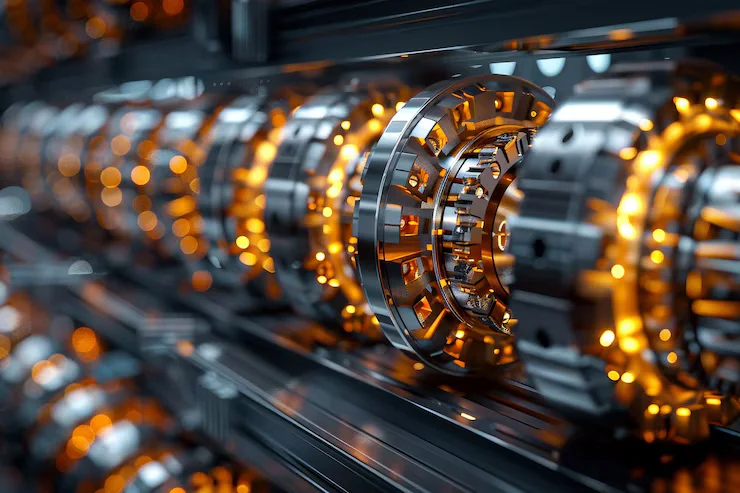

An electric motor winding machine is a specialized piece of equipment designed to wind copper or aluminum wire onto the stator or rotor of electric motors. These machines have become vital in modern manufacturing environments due to their ability to reduce manual labor, increase production speed, and improve consistency. The winding process is one of the most important steps in motor construction, as it directly influences the performance, efficiency, and reliability of the final motor product.

Electric motor winding machines eliminate human error and ensure that every coil is placed precisely with the correct number of turns, wire tension, and placement. In today’s competitive manufacturing world, adopting such advanced machinery is not a luxury but a necessity.

Types of Electric Motor Winding Machines

Motor winding machines come in different types depending on the level of automation and intended application. Manual winding machines are the simplest form, requiring full operator involvement and often used for prototyping or small-batch production. Semi-automatic machines provide some automation, reducing the operator’s workload but still requiring supervision.

Fully automatic winding machines are the pinnacle of efficiency. These machines use programmable control systems to carry out the winding process without human intervention. They can handle different winding patterns, wire gauges, and motor sizes with incredible accuracy and speed.

Key Features of Modern Machines

Electric motor winding machines today come equipped with user-friendly interfaces, programmable settings, automatic wire feeders, tension controllers, and integrated quality control systems. These features ensure repeatable accuracy, reduced downtime, and seamless transition between different motor models. Real-time monitoring and automatic error correction further enhance their reliability.

The Role of Segmented Stator Winding

What Is Segmented Stator Winding?

Segmented stator winding is a technique in which the stator, instead of being a single continuous structure, is divided into individual segments or teeth. Each segment is wound separately and then assembled into a full stator. This approach contrasts with traditional methods where the stator is wound as a single piece, which can be complex and time-consuming.

This method simplifies the winding process and makes it compatible with automated machinery. The separate segments allow for easier access and better control of the wire during winding. As a result, the technique is rapidly gaining traction in industries focused on efficiency and high-volume production.

Benefits of Segmented Stator Winding

Segmented stator winding offers numerous benefits. It allows for more efficient wire placement, which improves the slot fill factor. A higher fill factor leads to better electrical performance and reduced energy loss. Additionally, segmented designs improve heat dissipation, as each coil has more exposure to cooling surfaces.

This method also supports more compact and lightweight motor designs. Motors with segmented stators are generally more efficient and easier to manufacture in large quantities. The modular nature of this approach makes it easier to automate and scale.

How Electric Motor Winding Machines Improve Speed

Automation Minimizes Human Error

Electric motor winding machines minimize human involvement in the winding process. Through the use of software-controlled programs, these machines execute winding tasks with extreme precision. Once the parameters are set, the machine performs the same operation repeatedly without fatigue or variation.

The reduction of human error leads to better product consistency and fewer defects. Automated error detection systems notify operators of any issues immediately, ensuring a smooth and reliable production process.

Faster Turn Execution

One of the most obvious advantages of electric motor winding machines is speed. These machines are capable of winding hundreds or even thousands of turns in just a few minutes. This capability drastically reduces production time compared to manual or semi-automatic methods.

With segmented stator winding, the speed benefit becomes even more pronounced. Each segment can be wound quickly and efficiently, and once completed, the stator is assembled. This modular approach cuts down production time significantly.

Simultaneous Multi-Spindle Winding

Advanced winding machines come equipped with multiple spindles, allowing for the simultaneous winding of several coils. This feature is especially useful in mass production settings. With proper synchronization, these machines can produce multiple wound segments at the same time, boosting throughput without increasing labor costs or workspace requirements.

Seamless Integration with Segmented Stator Design

Electric motor winding machines are ideally suited for segmented stator designs. Since each segment is a standalone piece, machines can be configured to wind each one individually and with optimal precision. Once the segments are complete, they are fitted together to form a full stator. This seamless integration reduces complexity and increases efficiency.

Reduced Setup and Downtime

Another significant advantage is the ease of setup. Modern winding machines come with memory settings that store specifications for various motor types. Operators can switch between motor models quickly, minimizing downtime between production runs.

This feature is particularly valuable for companies that produce a wide range of motors and need the flexibility to switch between products quickly and efficiently.

Applications Across Industries

Automotive Manufacturing

In the automotive sector, electric motors are used in a wide array of applications, including electric vehicles (EVs), power steering systems, and window regulators. With rising demand for EVs, the need for efficient motor manufacturing has skyrocketed. Winding machines with segmented stator capabilities allow manufacturers to meet these demands quickly and effectively.

Consumer Electronics

Electric motors are also used in a variety of consumer appliances, from washing machines and refrigerators to fans and air conditioners. High-speed winding machines make it possible to produce compact, efficient motors in large quantities, helping manufacturers meet market demands without compromising on quality.

Industrial Automation

In industrial settings, automation equipment and robotics rely heavily on reliable and high-performance electric motors. Consistent coil winding is essential for ensuring that these motors can perform under strenuous conditions without failure. Automated winding systems make this possible while also supporting high-volume production.

Renewable Energy Systems

Renewable energy systems such as wind turbines and solar trackers require large, efficient electric motors. These motors must be durable, reliable, and capable of operating in various environmental conditions. Electric motor winding machines and segmented stator winding techniques help manufacturers produce such motors efficiently, contributing to the growth of sustainable energy technologies.

Quality and Performance Improvements

Enhanced Accuracy

The accuracy of automated winding machines ensures that each coil meets exact specifications. This level of precision directly translates to better motor performance, as uniform coil placement minimizes resistance and energy loss.

Consistent Quality Control

Quality control is built into the operation of electric motor winding machines. Machines continuously monitor tension, wire placement, and number of turns, ensuring that each coil meets the same standard. This uniformity is critical in industries where reliability and performance are paramount.

Better Thermal Management

Segmented stator winding allows for better spacing and coil arrangement, which improves heat dissipation. This is essential for motors that operate under high loads or in confined spaces, as it helps prevent overheating and extends motor life.

Improved Power Density

By allowing more turns to be wound in a limited space, segmented stator winding improves the magnetic performance of the motor. This results in greater power output without increasing motor size, which is especially valuable in applications where space is limited.

Economic Advantages

Reduced Labor Costs

One operator can oversee multiple winding machines, significantly reducing the need for skilled labor. This reduction in labor not only saves costs but also helps address labor shortages.

Lower Material Waste

Electric motor winding machines use precise wire measurement and control systems to minimize waste. This not only saves material costs but also contributes to a more sustainable production process.

Faster Time to Market

With increased production speed and fewer defects, manufacturers can bring their products to market faster. This gives companies a competitive edge, especially in fast-growing sectors such as electric vehicles and renewable energy.

Scalable Production

As demand grows, manufacturers can scale their operations by adding more machines without compromising quality. Automated systems allow for seamless expansion with minimal disruption.

Challenges and Solutions

Despite their advantages, electric motor winding machines do present certain challenges. However, these can be effectively managed with the right strategies.

Coil Overlap or Wire Breakage

This issue can occur when tension is not properly controlled. Modern machines come with advanced tension sensors and real-time monitoring that help prevent such problems before they escalate.

Complex Stator Shapes

Not all stators are designed the same. Some have complex geometries that make winding difficult. Segmented stator winding solves this by allowing each piece to be wound separately, regardless of the final shape.

High Initial Investment

While automated machines require a significant upfront investment, the long-term benefits—such as reduced labor costs, faster production, and fewer defects—quickly justify the expense.

Future Trends in Winding Technology

The future of electric motor winding is moving toward even greater efficiency and intelligence. Artificial intelligence and machine learning will allow winding machines to self-optimize, detect anomalies, and improve performance over time. IoT integration will enable remote monitoring and predictive maintenance, further reducing downtime.

Compact, mobile winding machines will make it easier for smaller workshops to enter the market. Environmentally friendly designs will reduce power consumption and material waste, aligning manufacturing with sustainability goals.

Choosing the Right Electric Motor Winding Machine

Choosing the right machine involves understanding your production requirements, including motor size, volume, and application. It’s important to select a machine that offers flexibility, ease of use, and support for segmented stator winding. Maintenance support, software updates, and scalability are also critical factors.

Conclusion

Electric motor winding machine and segmented stator winding technology are transforming the way motors are manufactured. These innovations offer unparalleled improvements in production speed, consistency, and scalability. As demand for electric motors continues to grow, especially in automotive, industrial, and renewable energy sectors, manufacturers must invest in advanced winding solutions to stay competitive.

By adopting these technologies, companies not only enhance their operational efficiency but also position themselves for long-term growth in a rapidly evolving market. The future of motor manufacturing lies in automation, precision, and intelligent design—starting with the right winding machine.