In chemical vapor deposition (CVD), maintaining precise control over gas delivery and temperature is vital for producing high-quality thin films. One key component in this process is the manifold, which ensures uniform gas flow and stable reaction conditions inside the chamber.

This article explores the essential role of the manifold in CVD systems why it must be kept hot, how heating methods prevent condensation, maintain reactivity, and support consistent deposition. You’ll also learn about temperature ranges, heating techniques, troubleshooting tips, and how advanced technologies like PECVD and ALD demand even greater precision in manifold design and control.

What Role Does the Manifold Play in CVD?

The manifold serves as the central distribution point for precursor gases in CVD equipment, ensuring uniform delivery to multiple wafers and maintaining process stability.

How Does Gas Flow Affect Thin Films

It directs the gas flow from source lines to the deposition chamber, ensuring uniform delivery to multiple wafers simultaneously. Inconsistent gas flow can negatively impact thin film deposition, leading to non-uniform thickness, surface defects, or reduced process stability.

Why Is Temperature Control Crucial in Manifolds

Maintaining a heated manifold ensures that precursor gases reach the deposition chamber in optimal condition and preserves the chemical activity required for high-quality thin film deposition.

Why Must the Manifold Be Kept Hot?

Keeping the manifold hot is critical to prevent condensation, maintain gas reactivity, ensure uniform flow, reduce clogging, and support stable deposition processes.

How Does Heating Prevent Gas Condensation

Precursor gases are prone to condensation when exposed to cooler surfaces, which can obstruct gas flow or change chemical composition. Proper manifold temperature minimizes condensation, preventing clogging and ensuring consistent delivery to the wafer surface.

How Is Gas Reactivity Maintained by Heat

Gas reactivity can decrease if precursor gases cool before reaching the deposition chamber. A heated manifold preserves chemical activity, improving thin film deposition rates and enhancing the quality of semiconductor devices.

How Does Heating Ensure Uniform Gas Flow

Uniform gas flow is essential for even wafer coverage. Heating the manifold reduces the risk of cold spots, which can cause uneven flow distribution, ensuring high process stability and consistent film thickness across the deposition chamber.

How Does Heat Reduce Clogging Risks

Cold manifolds or uneven heating can result in precursor gas condensation or polymer formation, causing clogging in the gas delivery system. Heating prevents these blockages, reducing maintenance needs and minimizing downtime in semiconductor fabrication lines.

How Does Temperature Support Process Stability

Stable temperature control in the manifold supports overall process stability. Maintaining the manifold within recommended temperature ranges allows for predictable thin film deposition and reduces variations in wafer deposition quality.

What Are Typical Manifold Temperature Ranges?

Manifold temperatures vary by precursor gas but must remain above condensation points and below decomposition temperatures for optimal performance.

How Do Temperatures Vary by Precursor Gas

Silane-based gases often require manifolds around 120–180°C, while metalorganic precursors used in MOCVD may need temperatures up to 200°C.

What Charts or Guidelines Improve Accuracy

Creating detailed charts of precursor-specific manifold temperatures helps optimize deposition and fills common gaps in competitor content.

How Are Manifolds Heated Effectively?

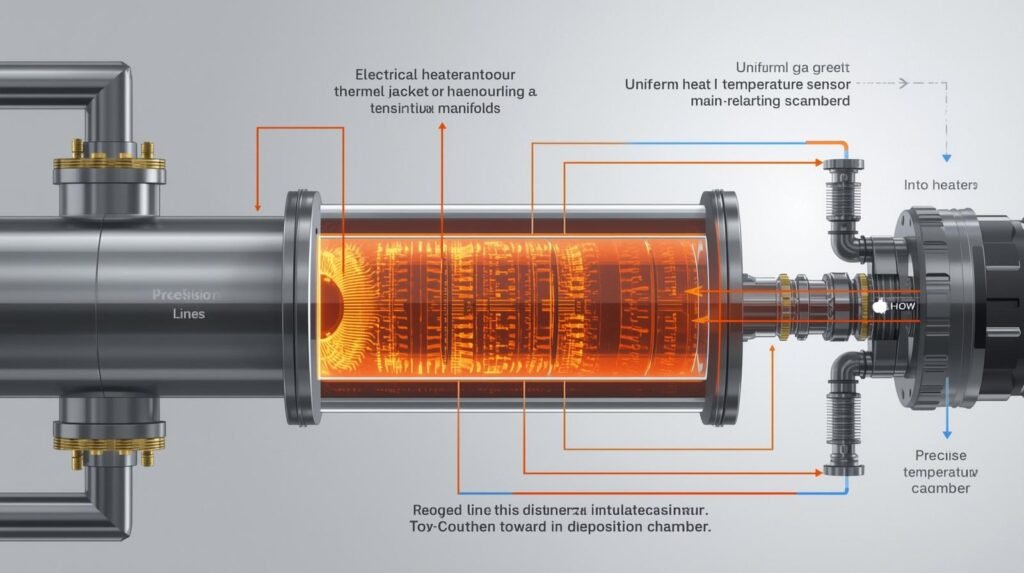

Various heating methods ensure uniform manifold temperatures, preserve gas reactivity, and prevent condensation.

What Are the Benefits of Electrical Heating

Trace heaters or resistive heating elements are often integrated along the manifold to provide consistent temperature control and allow rapid adjustments to match process requirements.

How Do Thermal Jackets Provide Uniform Heat

Thermal jackets encase the manifold and offer uniform heating along its length, commonly combined with temperature control systems to ensure steady heat distribution.

How Do Heated Gas Lines Prevent Condensation

Precursor gases may pass through heated transfer lines before entering the manifold, reducing condensation and preserving reactivity.

How Does Vacuum Insulation Improve Efficiency

Vacuum-insulated manifolds minimize heat loss and improve energy efficiency. Combining insulation with electrical or jacket heating ensures stable temperature control while reducing energy consumption.

How Does Manifold Temperature Affect Film Quality?

Manifold temperature directly affects thin film deposition uniformity, wafer coverage, and overall CVD yield.

How Does Heating Influence Deposition Yield

Incorrect heating can reduce film quality, lower deposition rates, and create localized variations on the wafer. Optimizing manifold heating ensures consistent gas reactivity and supports high process stability.

How Are Defects Minimized with Proper Heating

Proper manifold temperature control helps maintain uniform gas flow, minimizing surface defects and improving thin film quality in semiconductor devices.

How Can Manifold Heating Be Optimized for Energy?

Efficient manifold heating reduces energy consumption while maintaining deposition quality.

What Strategies Reduce Power Consumption

Combining thermal insulation, optimized heater placement, and precise temperature control minimizes energy use during CVD operations.

How Does Real-Time Monitoring Improve Efficiency

Monitoring manifold temperature in real time and adjusting heating power only when necessary helps maintain deposition quality while optimizing energy efficiency.

What Are Common Manifold Heating Issues?

Manifold heating issues can lead to uneven gas flow, condensation, or reduced process stability. Stepwise troubleshooting ensures rapid resolution.

How Can Temperature Irregularities Be Detected

Verify uniform temperature along the manifold with thermocouples to identify cold spots or inconsistencies.

What Steps Fix Condensation or Flow Problems

Check for condensation or gas flow irregularities in the lines and adjust parameters to restore gas reactivity.

How Are Heaters and Jackets Troubleshot

Inspect heaters and thermal jackets for malfunction and recalibrate or repair as necessary to maintain process stability.

How Do Advanced CVD Processes Affect Manifolds?

Advanced processes like PECVD and ALD introduce new requirements for manifold heating and control.

Why Is PECVD Sensitive to Manifold Temperature

Low-temperature PECVD processes require precise temperature control to prevent plasma-induced condensation and ensure uniform thin film deposition.

How Does ALD Require Precise Gas Control

ALD demands consistent gas pulses and highly stable temperature environments, making manifold heating critical for film quality and process reliability.

What Future Trends Will Shape Manifold Design?

Future semiconductor gas delivery systems focus on automation, energy efficiency, and enhanced process control.

How Will Automation Improve Gas Flow

Integrated sensors and predictive algorithms allow adaptive heating and consistent gas flow, improving thin film deposition.

What Innovations Enhance Thin Film Quality

Advanced manifold designs and heating strategies support increasingly complex precursor chemistries and modern CVD techniques, optimizing film quality and process stability.

Conclusion

Maintaining a heated manifold in the CVD process is essential for stable gas flow, consistent film quality, and reliable semiconductor performance. Proper temperature control prevents condensation, preserves gas reactivity, and minimizes defects, ensuring every wafer receives uniform deposition.

As CVD technology advances, optimized manifold heating and intelligent temperature management will continue to play a vital role in achieving precision, efficiency, and high-yield results. Explore more detailed guides and expert resources on the Everytalkin homepage to stay ahead.

FAQs

What happens if the manifold temperature drops in CVD?

Gas condenses, causing flow blockage and poor film quality.

Why is uniform gas flow important in CVD?

It ensures even film thickness and stable wafer deposition.

Can overheating the manifold damage precursor gases?

Yes, excessive heat causes gas decomposition and contamination.

How does manifold heating affect production yield?

Proper heating increases yield by improving deposition consistency.

What causes condensation inside the CVD manifold?

Low temperatures or poor insulation cause gas condensation.

How do advanced sensors help in manifold control?

They maintain precise temperature and optimize heating performance.

Why is PECVD more temperature-sensitive than standard CVD?

Because plasma reactions require tighter temperature control stability.

Can manifold heating reduce energy consumption?

Yes, efficient control minimizes heat loss and power usage.