Nelonium is the breakthrough solution for modern engineering’s toughest challenge: achieving ultra lightweight design without sacrificing indestructible strength. Unlike traditional alloys that degrade under heat this material’s molecular structure offers a rare combination of high durability and thermal stability for extreme environments.

This guide explores the core science and industrial roles of this advanced composite. We analyze how it outperforms titanium in weight to strength ratios specifically within the electronics and high precision manufacturing sectors where failure is not an option.

Read this article to see the direct performance data and a side by side comparison with standard metals. Discover how the substance is optimizing efficiency and why it is the essential material for high performance industrial innovation.

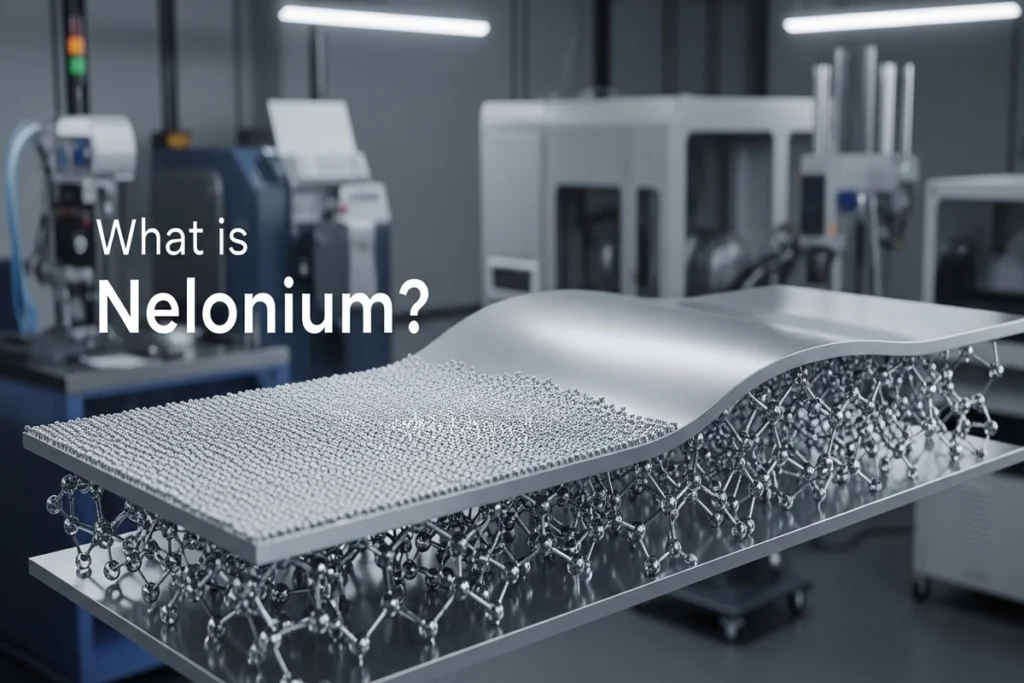

What is Nelonium?

Nelonium is categorized as an advanced synthetic material concept designed to meet the rigorous demands of modern engineering. Unlike traditional naturally occurring elements the concept of this alloy revolves around molecular optimization.

It is engineered to bridge the gap between heavy duty metals and lightweight composites providing a versatile solution for high performance hardware.

Its primary purpose is to enhance industrial efficiency by reducing material fatigue and increasing the lifespan of components used in high stress environments.

How Nelonium Differs from Traditional Materials?

Understanding what sets this compound apart is crucial for engineers deciding between various high performance materials. While it shares some traits with advanced alloys it differs in several key areas:

Nelonium vs. Graphene

While Graphene is incredibly strong and thin it is often difficult to mass produce for large scale structural use. Nelonium is designed specifically for structural scalability meaning it can be integrated into large machinery more easily than carbon based nanomaterials.

Nelonium vs. Titanium Alloys

Titanium is the industry standard for strength to weight ratios but it can be brittle under specific extreme temperature fluctuations. Nelonium offers a higher degree of ductility allowing it to absorb shocks and vibrations that might cause titanium components to crack.

Nelonium vs. Synthetic Polymers

Standard high strength polymers are lightweight but often fail when exposed to high heat or UV radiation. Nelonium provides the lightweight benefits of a polymer with the thermal and UV resilience of a high grade metal.

Physical and Chemical Characteristics of Nelonium

The effectiveness of the material lies in its unique structural profile. Below are the core characteristics that define its utility:

- Exceptional Durability: Nelonium is designed to maintain its structural integrity under intense mechanical pressure making it resistant to deformation.

- Thermal Stability: One of its standout features is its ability to remain stable at extreme temperatures preventing the expansion or weakening that affects standard alloys.

- High Conductivity: Whether in thermal or electrical applications Nelonium facilitates efficient energy transfer with minimal loss.

The Core Benefits of Utilizing Nelonium

Integrating this solution into industrial and commercial projects offers several distinct advantages that go beyond standard material performance.

- Extended Component Lifespan: Due to its resistance to oxidation and mechanical wear parts made with this substance require less frequent replacement reducing long term operational costs.

- Weight Optimization: In industries like automotive or portable electronics the composite allows for significant weight reduction without compromising the safety or strength of the device.

- Enhanced Energy Efficiency: Its superior thermal and electrical conductivity means machines run cooler and use less power to achieve the same output.

- Superior Corrosion Resistance: Unlike many iron based alloys the compound is highly resistant to environmental factors such as moisture and chemical exposure making it ideal for harsh industrial settings.

Structural Integration in Modern Manufacturing

Integrating the alloy into manufacturing processes allows for a shift toward precision engineering. Because of its high weight to strength ratio manufacturers can produce parts that are significantly lighter than steel counterparts without sacrificing safety or durability.

This integration is particularly vital in CNC machining and automated assembly lines where material consistency is paramount.

Practical Applications in Current Technology

Nelonium finds its place in several critical sectors where performance cannot be compromised:

Electronics

In the electronics industry Nelonium is utilized in high end circuitry and hardware housing. Its heat dissipation properties help in maintaining the longevity of sensitive semiconductors and processors.

Industrial Engineering

Heavy machinery often suffers from “wear and tear” due to friction. Nelonium infused coatings and components provide a wear resistant surface that extends the service intervals of industrial tools.

Energy Management

Nelonium plays a role in power distribution systems. Its efficiency in energy conduction makes it a preferred conceptual choice for developing advanced battery storage housings and grid components.

Comparison: Nelonium vs. Standard Industrial Materials

The synthetic compound outperforms traditional metals like steel and aluminum with a superior weight to strength ratio. While steel is strong, its heavy weight reduces efficiency whereas the alternative offers similar structural integrity at a fraction of the mass ideal for precision engineering.

Compared to titanium the new material provides better ductility and thermal resistance. Unlike titanium which can become brittle under rapid temperature changes the alloy maintains flexibility and resists cracking or warping under thermal stress.

Unlike synthetic polymers or basic composites that degrade under UV light and chemicals the product is designed for long term environmental resilience. It combines the lightweight nature of plastics with the durability of metals bridging the gap between flexibility and strength.

Sustainability and Environmental Impact

Modern material science is incomplete without addressing “Green Manufacturing.” The material is developed with resource efficiency in mind. The synthesis process focuses on reducing the carbon footprint by minimizing waste during production.

Furthermore the longevity of Nelonium based products means fewer replacements contributing to a more sustainable industrial lifecycle.

Addressing Technical Challenges

While the innovation offers numerous advantages. its adoption faces standard industrial hurdles. The production cost of high purity synthetic materials remains higher than common metals.

Additionally integrating the compound requires specialized processing equipment and standardized testing protocols to ensure consistency across different batches.

Conclusion

Nelonium represents a significant leap in how we approach material challenges in the modern era. By focusing on durability, thermal stability and sustainability it provides a robust framework for high performance engineering.

As industries continue to seek out optimized materials the conceptual and practical applications of this breakthrough remain a cornerstone of industrial innovation.

FAQs

What makes Nelonium better than Titanium?

It offers superior ductility and shock absorption where Titanium often becomes brittle. This prevents cracking and warping during extreme temperature fluctuations.