Printed circuit boards (PCBs) are at the heart of almost every electronic device. Whether it’s a smartphone, a medical device, or an industrial control system, engineers must consider not only the design and functionality of the PCB but also the cost involved in bringing it to life. Understanding the PCB manufacturing cost breakdown helps engineers optimize designs, reduce expenses, and ensure smoother production runs.

This article explores the main cost factors, from raw materials to assembly, so engineers can make informed decisions during the design and manufacturing process.

Introduction to PCB Manufacturing Costs

When a PCB goes from concept to production, many elements add to its final price. Costs vary depending on board complexity, production volume, turnaround time, and quality requirements. Engineers often face the challenge of balancing performance and budget. To do this, a solid grasp of cost drivers is essential.

By understanding the breakdown of these expenses, engineers can identify which areas offer room for savings and which are non-negotiable.

Major Factors Influencing PCB Manufacturing Costs

1. Raw Material Selection

The material forms the base of every PCB. The most common is FR-4, a fiberglass-reinforced epoxy laminate. While it is cost-effective, high-frequency or high-temperature applications require alternatives like Rogers, polyimide, or aluminum substrates.

- Standard FR-4: Lower cost, widely available.

- High-performance materials: More expensive, used for RF, aerospace, or automotive applications.

The thicker and higher-quality the laminate, the more it increases the total cost.

2. Board Size and Thickness

The physical size and thickness of the PCB directly affect manufacturing cost. A larger board consumes more material and requires bigger panels. Similarly, thicker boards need more copper and laminate, adding to expenses.

For engineers, optimizing layout to reduce wasted panel space can yield significant savings.

3. Layer Count

One of the most critical cost drivers is the number of layers.

- Single-layer PCBs are the cheapest.

- Double-layer PCBs cost more due to additional drilling and plating.

- Multilayer PCBs (4, 6, 8 layers and above) increase costs exponentially because of added lamination cycles, alignment precision, and extra materials.

High-density interconnect (HDI) boards with microvias and blind vias further push costs upward.

4. Copper Thickness

The thickness of copper used in PCB traces influences both performance and cost.

- Standard copper thickness: 1 oz (35 µm), economical for most consumer electronics.

- Heavy copper PCBs: 2 oz, 3 oz, or more, required for power electronics and high-current applications, significantly raising costs.

Since copper prices fluctuate globally, they also directly impact PCB pricing.

5. Surface Finish

A PCB’s surface finish ensures solderability and protects exposed copper. Several options are available, each with cost implications:

- HASL (Hot Air Solder Leveling): Low cost, suitable for less demanding applications.

- ENIG (Electroless Nickel Immersion Gold): More expensive, widely used for fine-pitch components and long shelf life.

- OSP (Organic Solderability Preservative): Cost-effective but less durable.

- Immersion Silver or Tin: Mid-range pricing, used in specific cases.

Engineers must balance cost with performance and assembly requirements when choosing finishes.

6. Drilling and Via Technology

Drilling accounts for a considerable part of PCB expenses. Traditional through-hole vias are less costly, but microvias, blind vias, and buried vias require laser drilling and precise plating, which significantly increase costs.

Additionally, the number and diameter of holes impact production time and tooling wear.

7. Solder Mask and Silkscreen

While seemingly minor, solder mask color and silkscreen also contribute to costs.

- Green solder mask: Standard and cheapest.

- Custom colors (black, red, blue, white): Slightly more expensive.

- High-contrast silkscreens or multiple colors: Add further expenses.

Engineers typically stick with standard green to save costs unless aesthetics are critical.

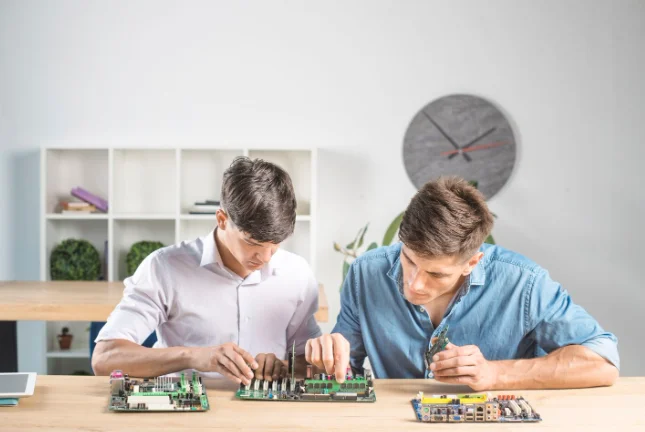

8. Assembly Process

Manufacturing doesn’t end with the bare PCB—assembly adds another layer of cost. Factors include:

- Component procurement: Sourcing parts at scale reduces expenses, but rare or obsolete components raise costs.

- Soldering method: Surface-mount technology (SMT) is cost-effective for high volumes, while through-hole assembly is more labor-intensive.

- Stencil preparation and setup: Fixed costs that become more affordable in larger runs.

Engineers should aim for component availability and design for manufacturability (DFM) to minimize assembly costs.

9. Testing and Quality Assurance

Every PCB must undergo testing to verify functionality and reliability.

- Flying probe testing: Suitable for small batches, lower upfront costs but slower.

- Bed-of-nails testing: Expensive to set up but efficient for mass production.

- X-ray inspection: Required for BGAs and hidden solder joints, adding to overall cost.

Though testing adds expense, skipping it risks product failure and long-term costs.

10. Production Volume and Turnaround Time

- Low-volume orders: Higher per-unit cost due to setup charges.

- High-volume production: Economies of scale reduce unit cost.

- Quick-turn PCBs: Expedited manufacturing demands premium pricing, as manufacturers must prioritize production and logistics.

Engineers planning ahead can save significantly by avoiding rush orders.

Hidden Costs Engineers Should Consider

Beyond the obvious factors, there are hidden costs that engineers must not overlook:

- Design revisions: Errors in design files or Gerbers can lead to rework charges.

- Tooling fees: Some manufacturers charge for stencils, test fixtures, or setup.

- Yield loss: Complex boards may have lower yields, increasing effective cost.

- Logistics and shipping: International manufacturing may save on production but add significant shipping and tariff expenses.

Strategies for Engineers to Reduce PCB Costs

Optimize Design for Manufacturability (DFM)

Keeping track widths, clearances, and hole sizes within standard manufacturing capabilities prevents unnecessary complexity and cost.

Standardize Materials and Processes

Whenever possible, stick to industry-standard FR-4, green solder masks, and HASL or ENIG finishes to minimize expenses.

Minimize Layer Count

If performance requirements allow, design with fewer layers to cut costs significantly.

Plan for Volume Production

Batch orders reduce costs per unit. Engineers should collaborate with procurement teams to consolidate orders.

Early Communication with Manufacturers

Engaging PCB fabricators early in the design process helps identify cost-saving opportunities and prevents expensive redesigns.

Why Cost Awareness Matters for Engineers

Understanding the PCB manufacturing cost breakdown goes beyond budgeting. It directly impacts project timelines, product competitiveness, and long-term profitability. Engineers who design with cost in mind can deliver functional, reliable products while keeping expenses under control.

By considering materials, finishes, via technology, and assembly methods from the start, engineers can strike the perfect balance between innovation and affordability.

Conclusion

PCB manufacturing involves many interrelated cost factors, from raw materials and board size to assembly and testing. For engineers, understanding these elements is crucial not only for reducing expenses but also for improving design quality and manufacturability.

By applying strategies such as optimizing design, standardizing materials, reducing unnecessary complexity, and planning production wisely, engineers can bring products to market more efficiently and cost-effectively.

In the end, knowledge of PCB manufacturing cost breakdown empowers engineers to make smarter design choices, ensuring that innovative ideas translate into successful, affordable products.