In the textile industry, ensuring fabric quality is critical to delivering durable and reliable products. One key aspect of fabric quality is its resistance to shrinkage. Shrinking fabric after production can lead to customer dissatisfaction and even product returns. To avoid these issues, manufacturers rely on tools like the fabric shrinkage tester, an essential device for evaluating the shrinkage rate of textiles.

Understanding Pre-Shrink Fabric

Pre-shrink fabric refers to textiles that have undergone a treatment process to minimize shrinkage during subsequent washes or usage. While most fabrics are prone to shrinkage due to moisture or heat, pre-shrinking ensures that the final product maintains its dimensions and structure after washing. However, the effectiveness of the pre-shrinking process must be tested rigorously to ensure consistency and reliability. This is where tools like the fabric shrinkage tester come into play.

The Importance of Fabric Shrinkage Testing

Shrinkage testing is essential for both textile manufacturers and garment producers. Here’s why it’s crucial:

- Maintaining Product Quality

Fabric shrinkage directly affects the quality and usability of garments. If a product shrinks excessively after purchase, it can render the garment unwearable or uncomfortable. With a reliable fabric shrinkage tester, manufacturers can ensure their textiles meet the highest quality standards. - Enhancing Customer Satisfaction

Consumers expect their clothing to retain its original shape and size even after multiple washes. Pre-shrink fabric ensures that garments meet this expectation, helping brands build trust and customer loyalty. - Ensuring Compliance with Industry Standards

Many industries have strict quality benchmarks for textiles. Shrinkage testing ensures that the fabric complies with these standards, whether for fashion, upholstery, or industrial use. - Reducing Returns and Complaints

Excessive fabric shrinkage often leads to customer complaints and returns, resulting in additional costs for businesses. By using shrinkage testing, companies can minimize such issues and improve profitability.

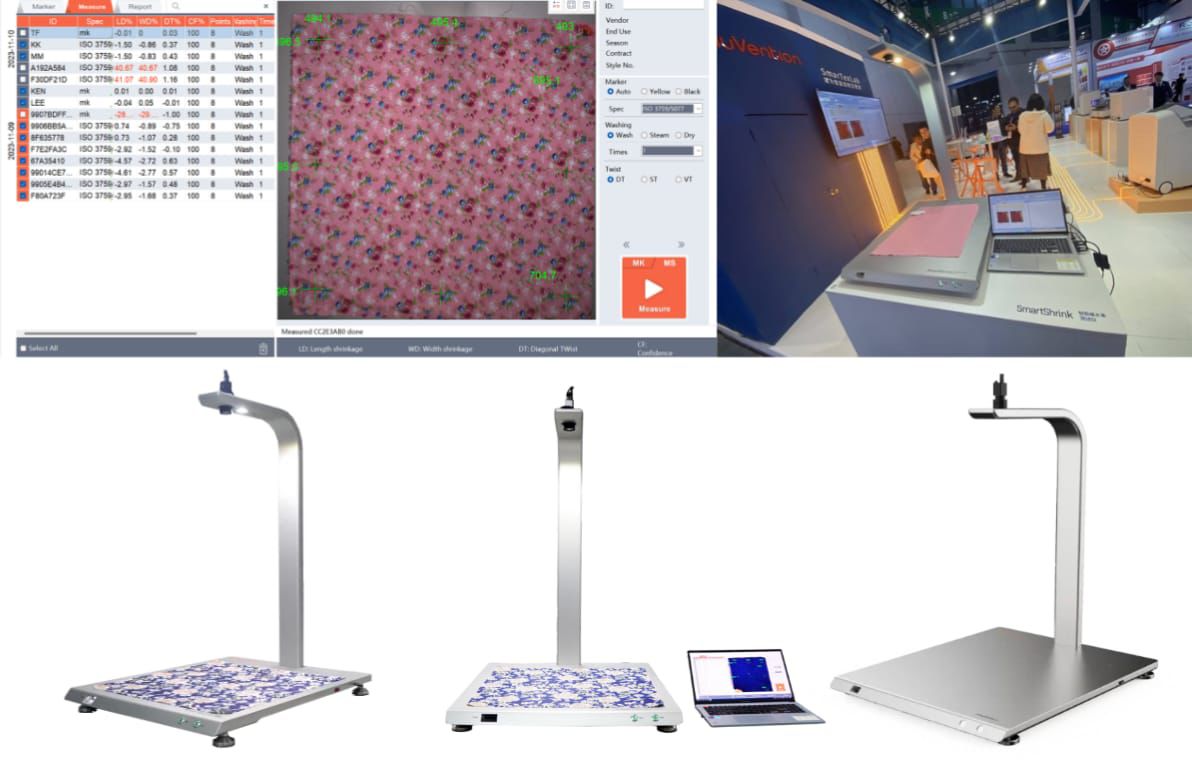

The Role of SmartShrink in Shrinkage Testing

For accurate shrinkage testing, manufacturers need advanced and reliable equipment like the SmartShrink Fabric Shrinkage Tester. This innovative tool is designed to deliver precise measurements of fabric shrinkage rates, making it a valuable asset for textile producers.

Features of the SmartShrink Tester

- High Accuracy

The SmartShrink Tester provides accurate results, allowing manufacturers to assess fabric shrinkage with confidence. - User-Friendly Design

The device is easy to use, making it ideal for manufacturers seeking efficient and hassle-free shrinkage testing. - Versatile Applications

The SmartShrink Tester works on various types of fabrics, including cotton, polyester, and blends, ensuring its usefulness across different industries. - Durability and Reliability

Built for industrial use, the SmartShrink Tester ensures consistent performance over time.

Benefits of Pre-Shrink Fabric

Using pre-shrink fabric offers numerous advantages for both manufacturers and consumers. For manufacturers, it reduces the risk of shrinkage-related complaints, ensuring their products remain competitive in the market. For consumers, it ensures garments retain their original size and shape, enhancing wearability and satisfaction.

Conclusion

In today’s competitive textile industry, maintaining fabric quality is non-negotiable. Tools like the fabric shrinkage tester play a pivotal role in ensuring that pre-shrink fabrics meet high standards of durability and consistency. By investing in reliable testing equipment like the SmartShrink Tester, manufacturers can produce superior textiles, ensuring customer satisfaction and building a strong reputation in the market.